The ART LabPlate reactor is a very efficient tool for gaining first-hand experience with flow chemistry. The intention is to help chemists to easily judge if their reactions are suitable for flow chemistry. But the story does not end there. The LabPlate is the first in a range of reactors, and the conditions in the LabPlate can be scaled up to the ART Plate Reactor production units in an easy way. This means reduced time and money in the transfer from development to production.

The LabPlate reactor is ideal for a wide range of applications. The main uses are for process development, exothermic and hazardous reactions, intermediates that are unstable under reaction conditions as well as for determining reaction rates. It is suitable for liquid/liquid reactions and for reactions completed within minutes.

The LabPlate reactor consists of two plates, which are similar to the plates used in production scale plate reactors. This gives the benefits of high heat transfer, optimum mixing and the ability to be flexible in the performance of the reaction.

Alfa Laval ART® LabPlate™ The reactor for an easy introduction to flow chemistry

Alfa Laval ART® LabPlate™ Each plate has one main process inlet and process outlet.

Secondary ports that make it possible to add reactants, take samples and measure are positioned along the length of the plate. This gives the user the flexibility to quickly explore new reactions and reaction conditions. The plates are stacked in a frame to give a wide operating range.

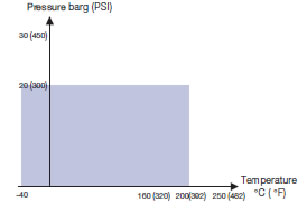

The LabPlate is developed to enable users to have the same condition in the laboratory as in the production plant. By having the possibility to use elevated pressures and temperatures,new and optimized reactor conditions can be achieved. With temperatures up to 200°C and with pressures of 20 barg, the envelope of operations is increased. For all design data see below.

Design pressure: FV to 20 bar g (300 psi)

Design Temperature: -40°C (-40°F) to + 200°C (+390°F)

Flow range: 2 – 40 ml/min

Residence time: 15 – 300 s

Material: 316L

Connections: 1/8" pipe (main inlet and outlet), 1/16" pipe for the ports

Dimensions: 550x170x240 mm, (21.7x6.7x9.4 inches)

Weight: 45 kg (99.2 lb)

Operating pressure and temperature are in the shaded area of the graph

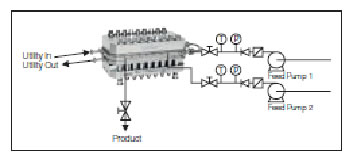

The ART LabPlate is a reactor which needs to be connected to a flow system to work. In a laboratory environment a system can be easily assembled from available items. The drawing below shows a basic system with main components. As always the parts in a system are determined by the chemistry and chemicals used. Alfa Laval Reactor Technology would be happy to help to suggest different components from our extensive experience or to help you contact an engineering company which builds flow system.

The Alfa Laval reactor technology team is ready to help in selecting the most appropriate Plate Reactor model and they are also able to support your flow chemistry efforts, including:

Up-to-date Alfa Laval contact details for all countries are available on the company website at www.alfalaval.com